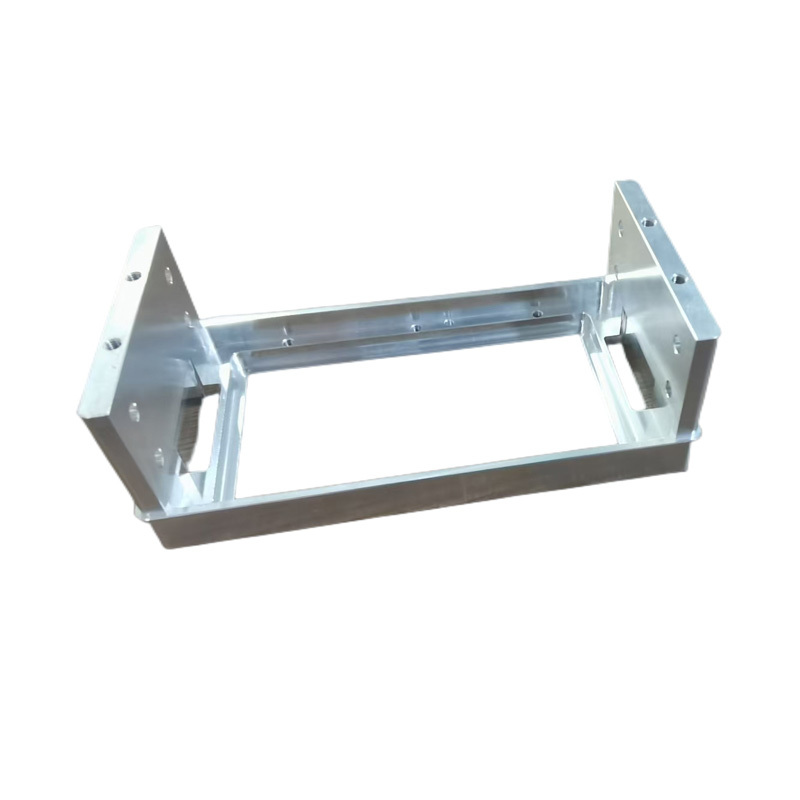

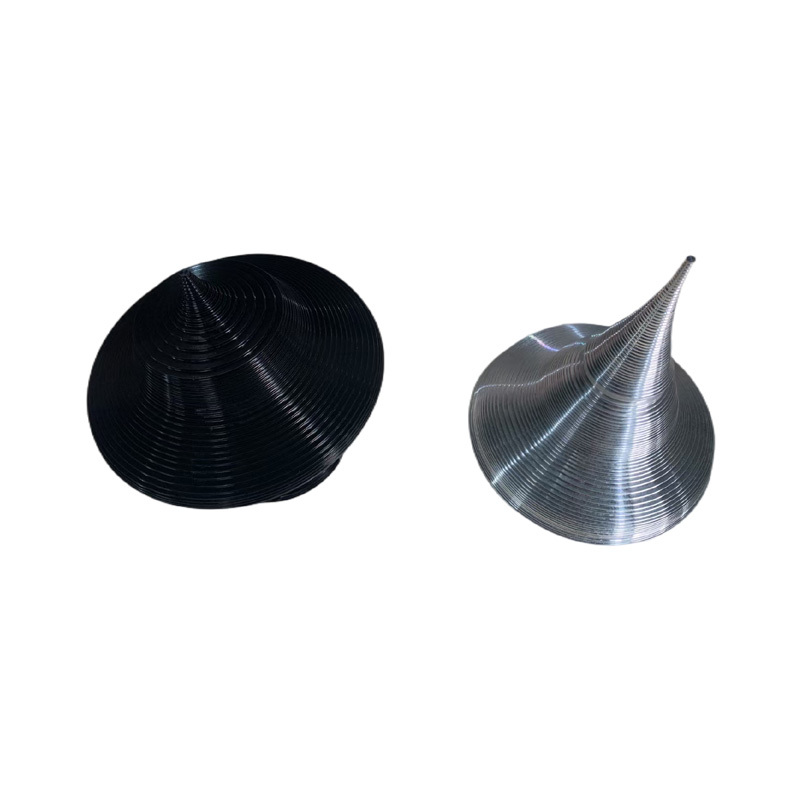

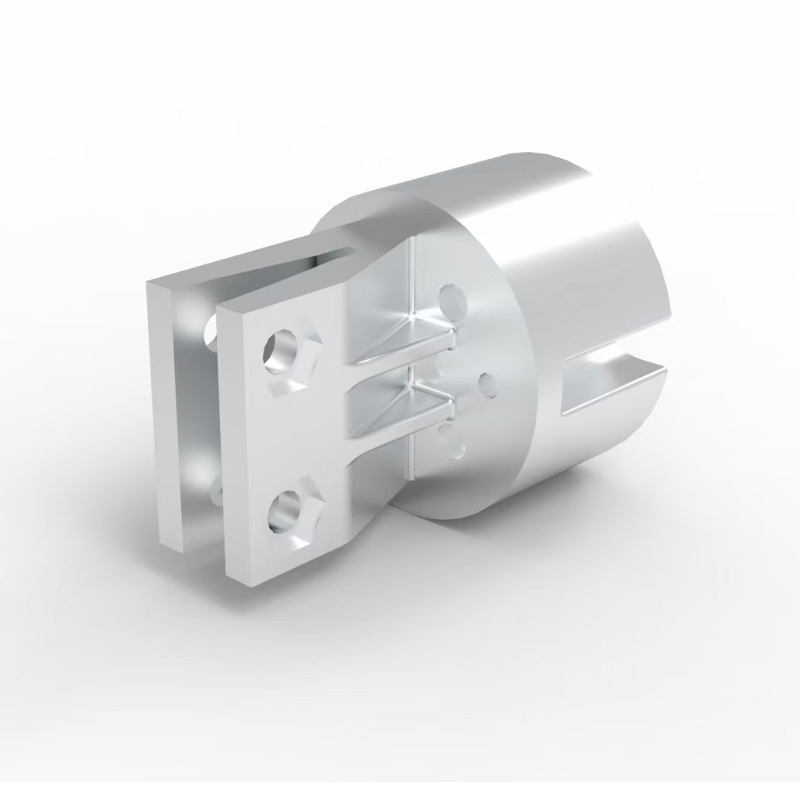

Die casting parts

Category:

Product Description

Materials: Aluminum ADC12, A380, AlSi10Mg etc.

Zinc: Zamak 3, Zamak 5, Zamak 8 etc.

Brass, Cooper, Titanium Alloy etc

Tolerance: +/-0.05mm - +/-0.03mm

Surface Treatment: Anodize, Bead blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurling, Laser/Etch/Engrave etc.

Dimensions: According to your 2D, 3D Drawings

Surface Roughness: Min Ra0.1~3.2um

Quality Inspection: 100% QC Quality Inspection

Quality Assurance: ISO9001, SGS, RoHs

Testing Equipment: CMM, Tool Microscope, Multi-Joint Arm, Automatic Height Gauge, Manual Height Gauge, Dial gauge, Marble Platform, Roughness Measurement

Lead Time: 3-5 Days for Samples, 1-3 Weeks for Mass Production

The dimensional accuracy and surface finish achieved are also notable advantages. Components produced through die casting typically have smooth surfaces and tight tolerances directly out of the mold. This high level of precision ensures that the die casting parts fit and function perfectly with other components in an assembly, reducing the likelihood of malfunctions. The excellent surface quality often means that less finishing work is required before the parts are ready for use or for subsequent coating processes, further streamlining the production workflow.

In conclusion, the die casting process provides a powerful combination of strength, precision, complexity, and cost-efficiency. The consistent quality and performance of the resulting die casting parts make them indispensable in the manufacturing landscape. As industries continue to demand lighter, stronger, and more complex components, the role of die casting is likely to remain prominent, driving innovation and supporting the production of a wide array of modern goods.

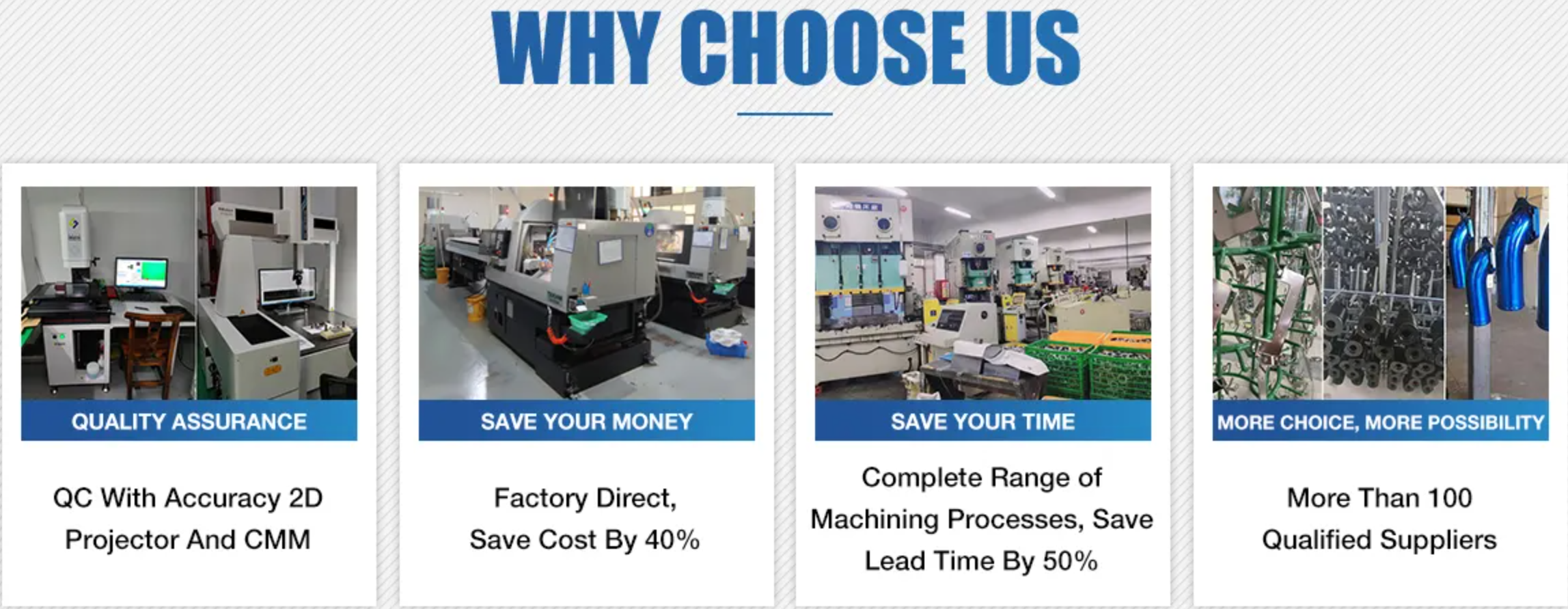

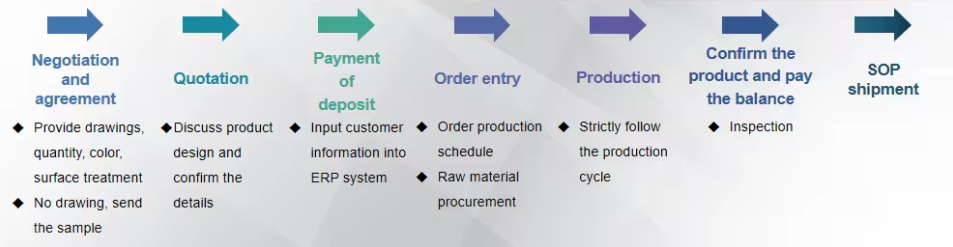

Our Process

One Stop Service, Meet Variety of Processing Need

Get a Custom Quote For Your Parts!

Key Words:

Die casting parts factory

Related Products

CNC Machining Parts

-

CNC Machining Parts

-

CNC Machining Parts

-

CNC Machining Parts

-

CNC Machining Parts

-

5 axis aluminum car turning parts cnc machining auto motorcycle spare parts cnc machining parts enclosure

CNC enclosures ensure safe, precise machining, while 5-axis aluminum turning parts enable complex, high-precision automotive components.

-

CNC Machining Parts

CNC machining parts deliver high precision, tight tolerances, and durable performance, supporting complex designs for automotive, aerospace, medical, and industrial uses.

CNC Milling Parts

-

steel milling

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

steel cnc parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

milling parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

milling parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

High precision set

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

high precision brass cnc milling parts

1. Material: Brass 2. Price: Factory Price 3. Surface Treatment (Finishing): Passivation 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

custom aluminum cnc machining milling parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

cnc parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

cnc machining parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

cnc machining parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

cnc machining brass parts

1. Material: Brass 2. Price: Factory Price 3. Surface Treatment (Finishing): Painting 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

brass cnc machining parts

1. Material: Brass 2. Price: Factory Price 3. Surface Treatment (Finishing): Nickel Plating 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

cnc machining parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

cnc machining parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

cnc machining parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

aluminum milling parts

1. Material: Aluminium 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

aluminum cnc parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Steel CNC Milling Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Galvanization 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

CNC Machining Steel Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Zinc Plating 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

cnc milling aluminum parts

1. Material: Aluminum 6061 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

CNC Turning Parts

-

steel turning parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

steel turning parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Precision Anodized Aluminum CNC Machining Milling Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Custom Aluminum CNC Machining Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

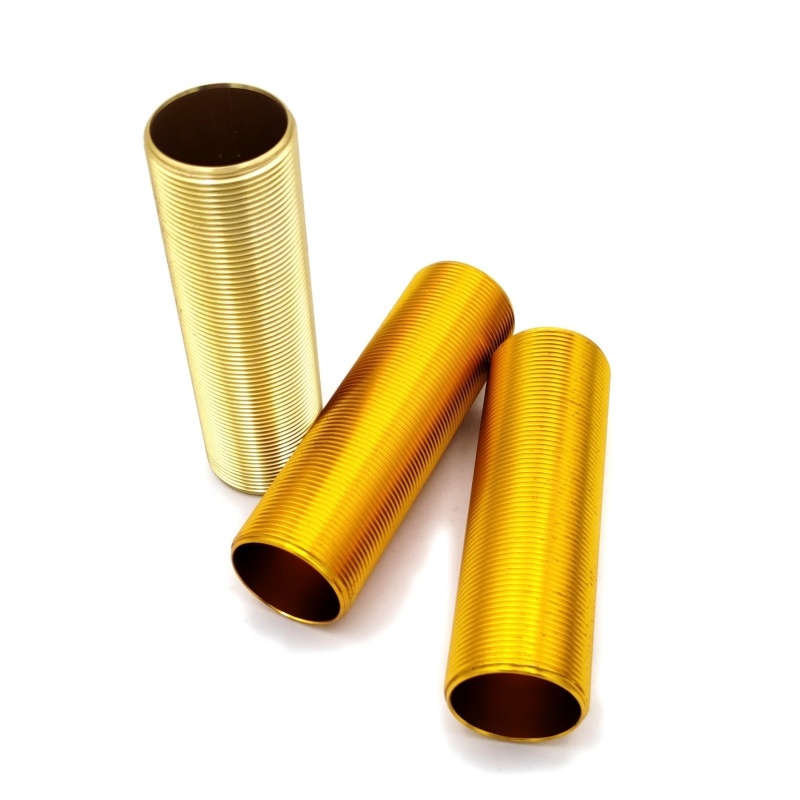

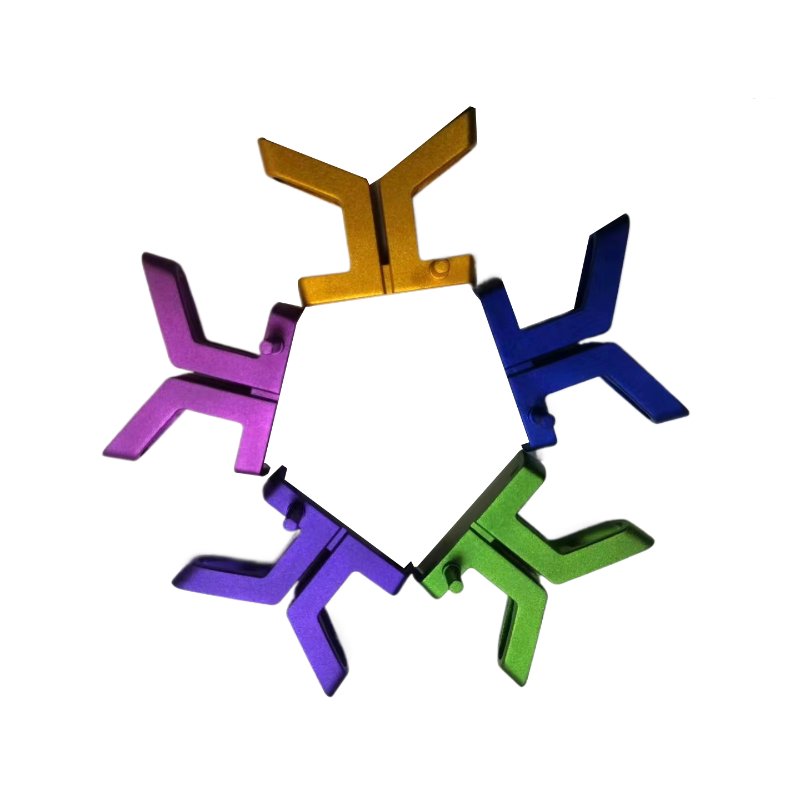

Color Anodized Precision CNC Machining Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Cnc Turning Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

CNC Precision Stainless Steel Machining Part

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Cnc Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Cnc Machining Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Cnc Machining Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Cnc Machining Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Brass Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Brass Cnc Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Brass CNC Machining Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Brass CNC Machining Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Brass CNC Machining Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Anodized Precision CNC Machining Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Anodized Precision CNC Machining Aluminum Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Aluminum Turning Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Aluminium Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Custom Metal CNC Turning Parts

1. Material: STEEL 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

CNC Swiss Lathe Machining

-

High Precision Steel 430F CNC Swiss Turning Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

High Precision CNC Swiss Turning Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Brass CNC Swiss Machining Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Aluminum CNC Swiss Turning Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

CNC High Precision Metal Machined Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

cnc machining parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

CNC stainless steel parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

CNC Swiss Lathe Machined Precision Metal Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Customized CNC Stainless Steel Machining PartS

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

High Precison Stainless Steel Parts machined by CNC Swiss Lathe

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.005mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

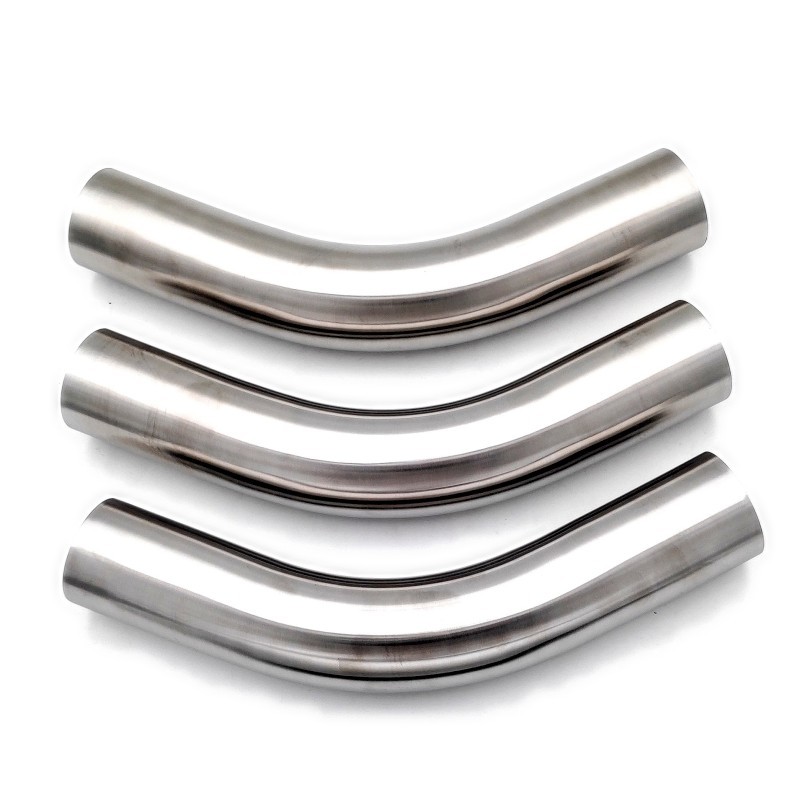

Tube Forming

-

304 ss elbow

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Bending, Welding, Drilling etc

-

Fishing gear

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Bending, Welding, Drilling etc

-

brass parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Bending, Welding, Drilling etc

Stamping Parts

-

Steel Stamping Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Steel Stamping Bending Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Stamping Steel Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Stamping Stainless Steel Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Stamping Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Stamping Copper Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Stamping Brass Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

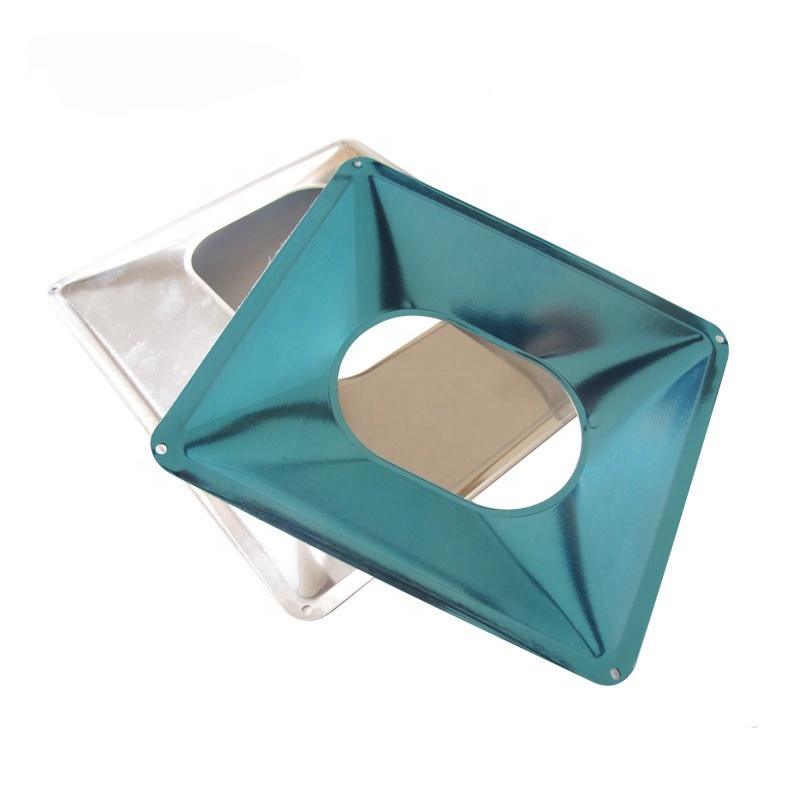

Stamping Aluminum Lamp Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Stainless Steel 304 Stamping Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Brass Stamping Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

-

Aluminum Stamping Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: CNC milling, CNC turning

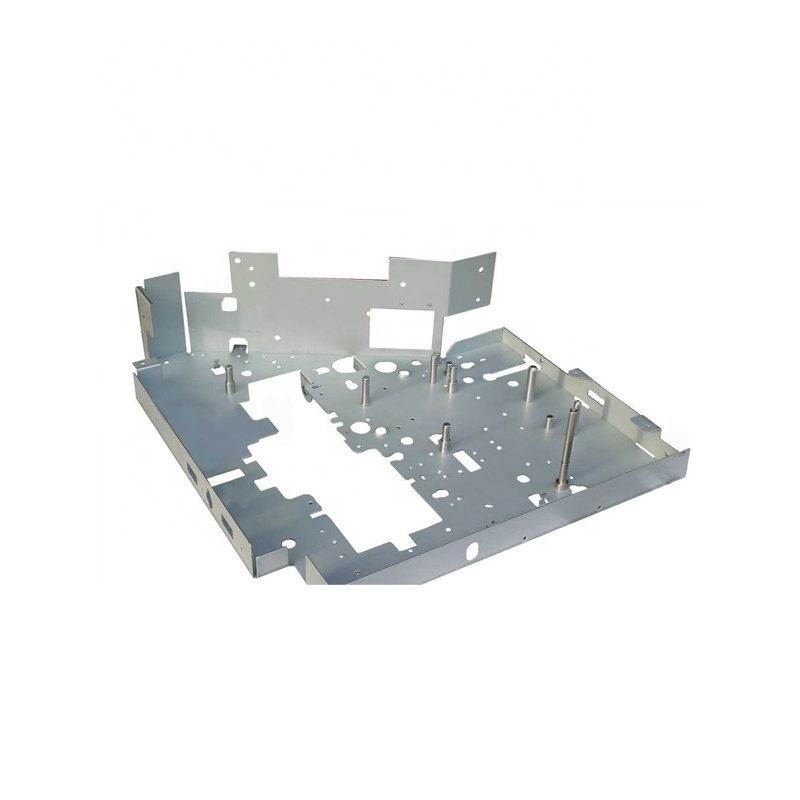

Sheet Metal Fabrication

-

Steel Sheet Metal Fabrication

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Stamping, Bending, Welding, Riveting etc

-

Steel Sheet Metal Bending Stamping Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Stamping, Bending, Welding, Riveting etc

-

Stamping Sheet Metal Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Stamping, Bending, Welding, Riveting etc

-

Stamping Bending Aluminum Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Stamping, Bending, Welding, Riveting etc

-

Stainless Steel Coil Springs

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Stamping, Bending, Welding, Riveting etc

-

Sheet Metal Part

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Stamping, Bending, Welding, Riveting etc

-

Sheet Metal Fabrication

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Stamping, Bending, Welding, Riveting etc

-

Sheet Metal Fabrication Coil Spring

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Stamping, Bending, Welding, Riveting etc

-

Laser Cutting Sheet Metal Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Stamping, Bending, Welding, Riveting etc

-

Bending Welding Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Stamping, Bending, Welding, Riveting etc

-

Aluminum Sheet Metal Parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Stamping, Bending, Welding, Riveting etc

-

Aluminum Sheet Metal Fabrication

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Stamping, Bending, Welding, Riveting etc

-

Sheet metal Fabrication

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Stamping, Bending, Welding, Riveting etc

-

Sheet metal Fabrication

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Stamping, Bending, Welding, Riveting etc

-

Sheet metal Fabrication

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Stamping, Bending, Welding, Riveting etc

-

Sheet metal Fabrication

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Stamping, Bending, Welding, Riveting etc

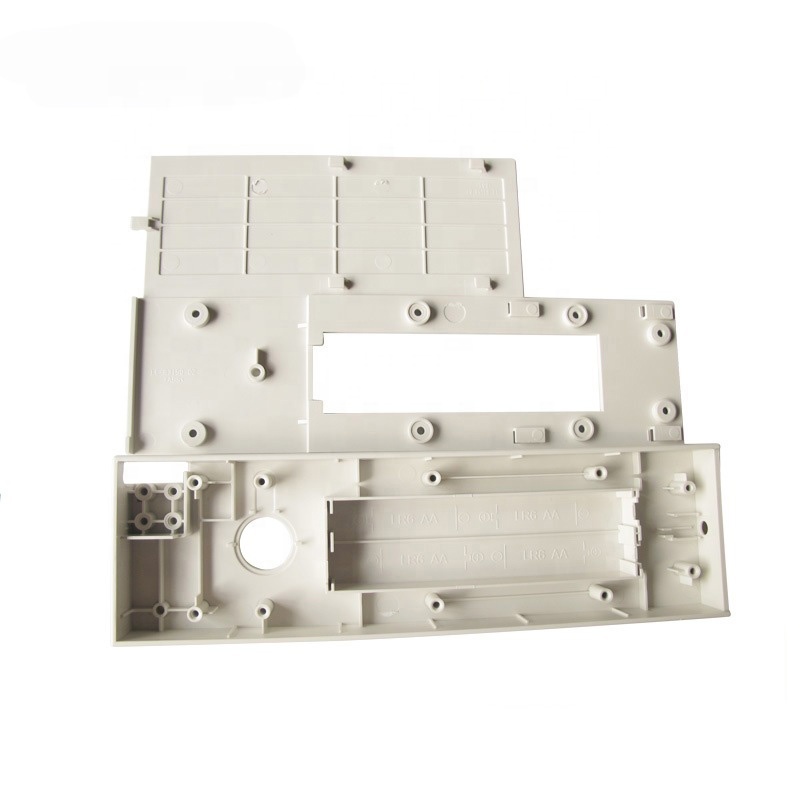

Plastic Injection Parts

-

PP Plastic Injection Parts

1. Material: Plastic 2. Price: Factory Price 3. Surface Treatment (Finishing): color as request 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Injection Molding

-

POM Plastic Injection Parts

1. Material: Plastic 2. Price: Factory Price 3. Surface Treatment (Finishing): color as request 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Injection Molding

-

Plastic Injection Moulding Parts

1. Material: Plastic 2. Price: Factory Price 3. Surface Treatment (Finishing): color as request 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Injection Molding

-

Plastic Injection Molding Parts With Brass Inserts

1. Material: Plastic 2. Price: Factory Price 3. Surface Treatment (Finishing): color as request 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Injection Molding

-

PC Plastic Injection Molding Parts

1. Material: Plastic 2. Price: Factory Price 3. Surface Treatment (Finishing): color as request 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Injection Molding

-

Custom Plastic Injection Parts

1. Material: Plastic 2. Price: Factory Price 3. Surface Treatment (Finishing): color as request 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Injection Molding

-

ABS Plastic Injection Parts

1. Material: Plastic 2. Price: Factory Price 3. Surface Treatment (Finishing): color as request 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Injection Molding

-

ABS Plastic Injection Molding Parts

1. Material: Plastic 2. Price: Factory Price 3. Surface Treatment (Finishing): color as request 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Injection Molding

-

Plastic Injection Parts

1. Material: Plastic 2. Price: Factory Price 3. Surface Treatment (Finishing): color as request 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Injection Molding

-

Plastic Injection Parts

1. Material: Plastic 2. Price: Factory Price 3. Surface Treatment (Finishing): color as request 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Injection Molding

-

Plastic Injection Parts

1. Material: Plastic 2. Price: Factory Price 3. Surface Treatment (Finishing): color as request 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Injection Molding

-

Plastic Injection Parts

1. Material: Plastic 2. Price: Factory Price 3. Surface Treatment (Finishing): color as request 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Injection Molding

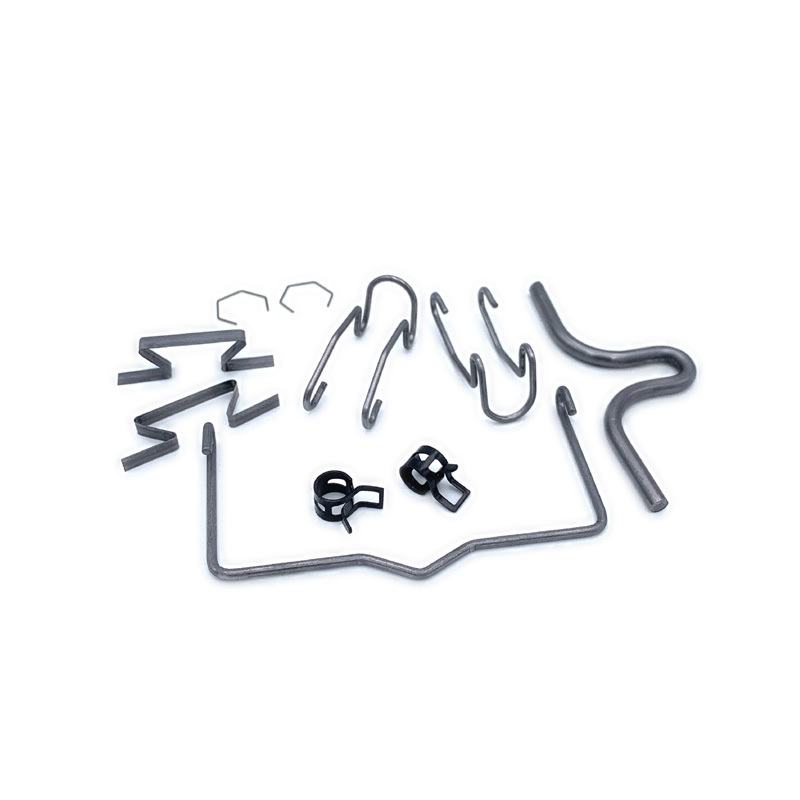

Wire Forming

-

Wire Forming Parts

1. Material: Steel 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Bending, Welding, Drilling etc

-

Powder Coating Steel Spings

1. Material: Steel 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Bending, Welding, Drilling etc

-

Car Pillow Bracket

1. Material: Steel 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Bending, Welding, Drilling etc

-

Wire Forming

1. Material: Steel 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Bending, Welding, Drilling etc

-

Wire Forming

1. Material: Steel 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Bending, Welding, Drilling etc

-

Wire Forming

1. Material: Steel 2. Price: Factory Price 3. Surface Treatment (Finishing): Anodized 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: Laser Cutting, Bending, Welding, Drilling etc

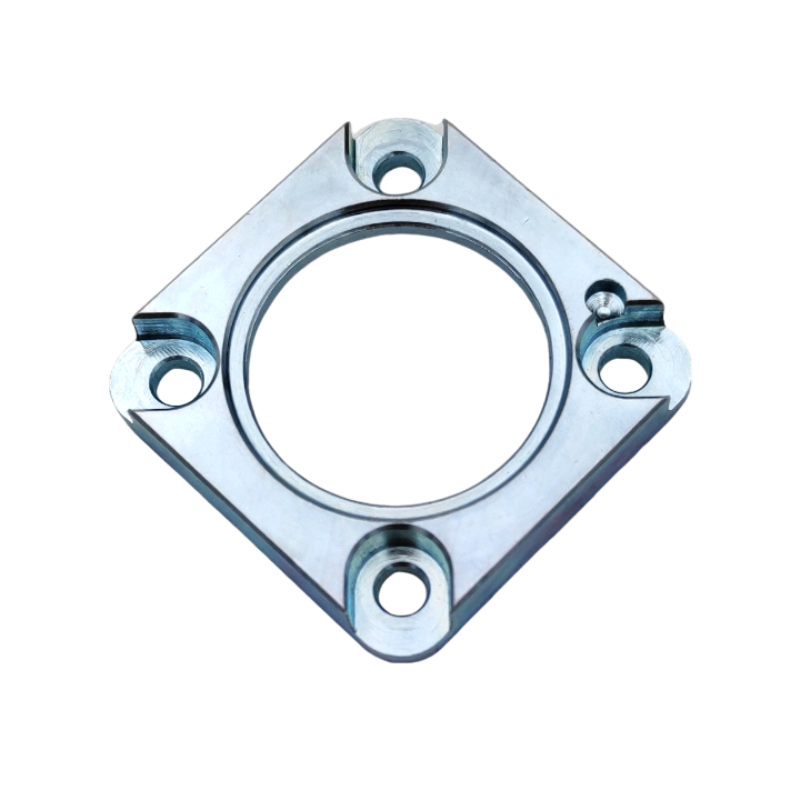

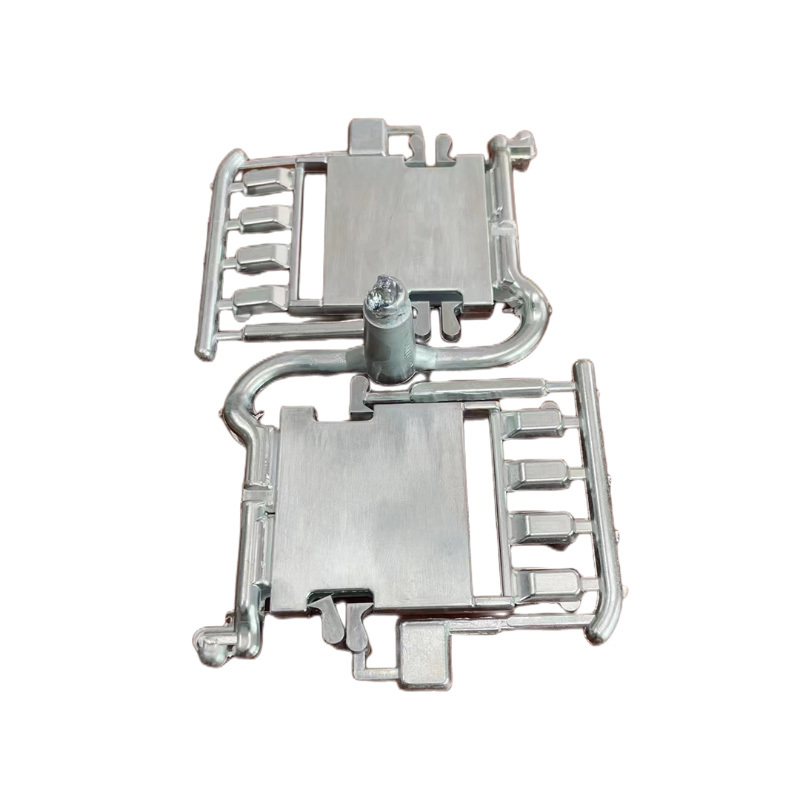

Die Casting Parts

-

Die Casting Anodizing Aluminum Ashtray

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Polishing 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: die casting, cnc machining

-

Die casting parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Polishing 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: die casting, cnc machining

-

Die casting parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Polishing 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: die casting, cnc machining

-

Die casting parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Polishing 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: die casting, cnc machining

-

Die casting parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Polishing 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: die casting, cnc machining

-

Die casting parts

1. Material: Aluminum 2. Price: Factory Price 3. Surface Treatment (Finishing): Polishing 4. Manufacturing Service: OEM or ODM is available. 5. Tolerance: down to +/-0.01mm, high accuracy 6. Specification: Products can be produced as per client’s drawings. 7. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 8. Manufacturing Processes and Procedures: die casting, cnc machining

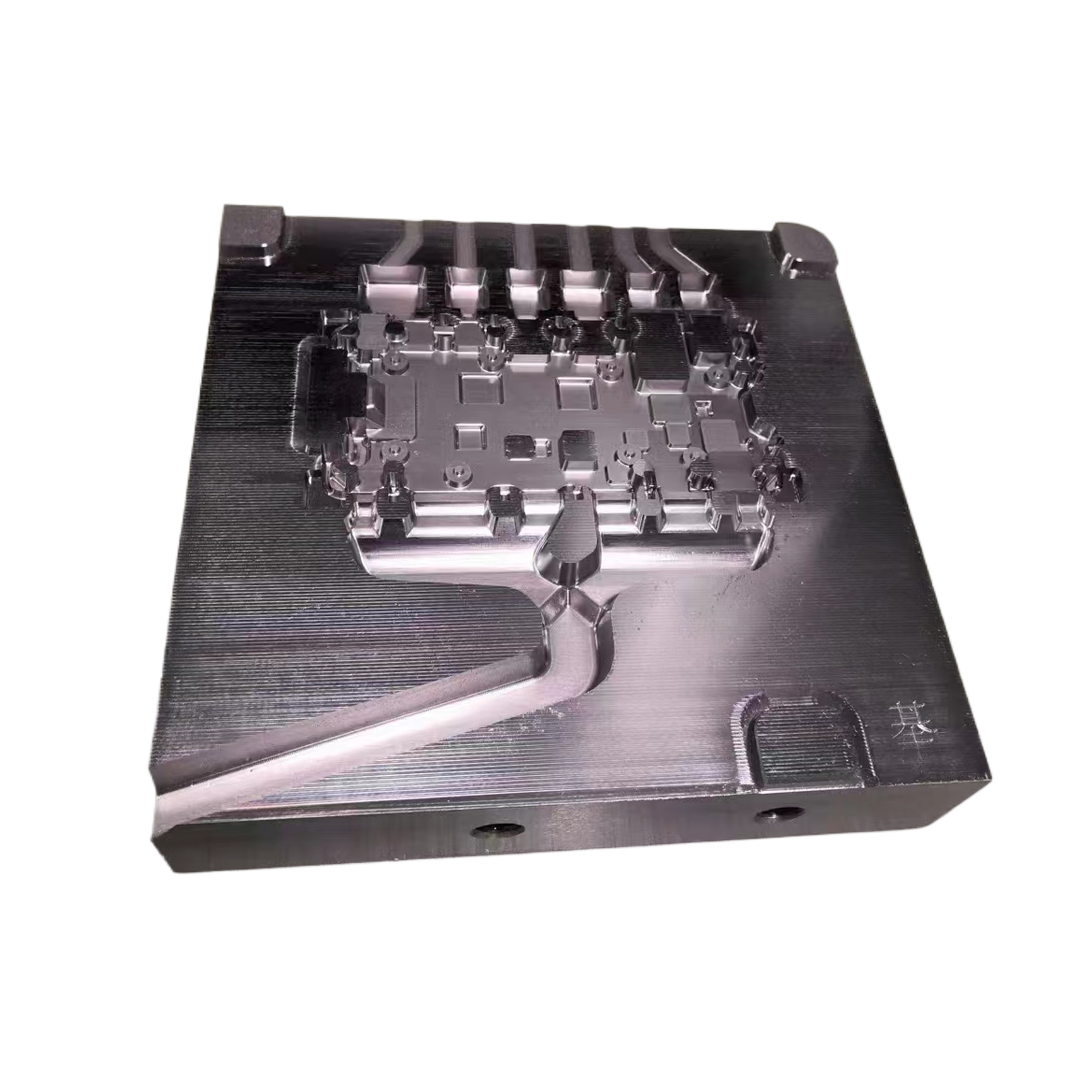

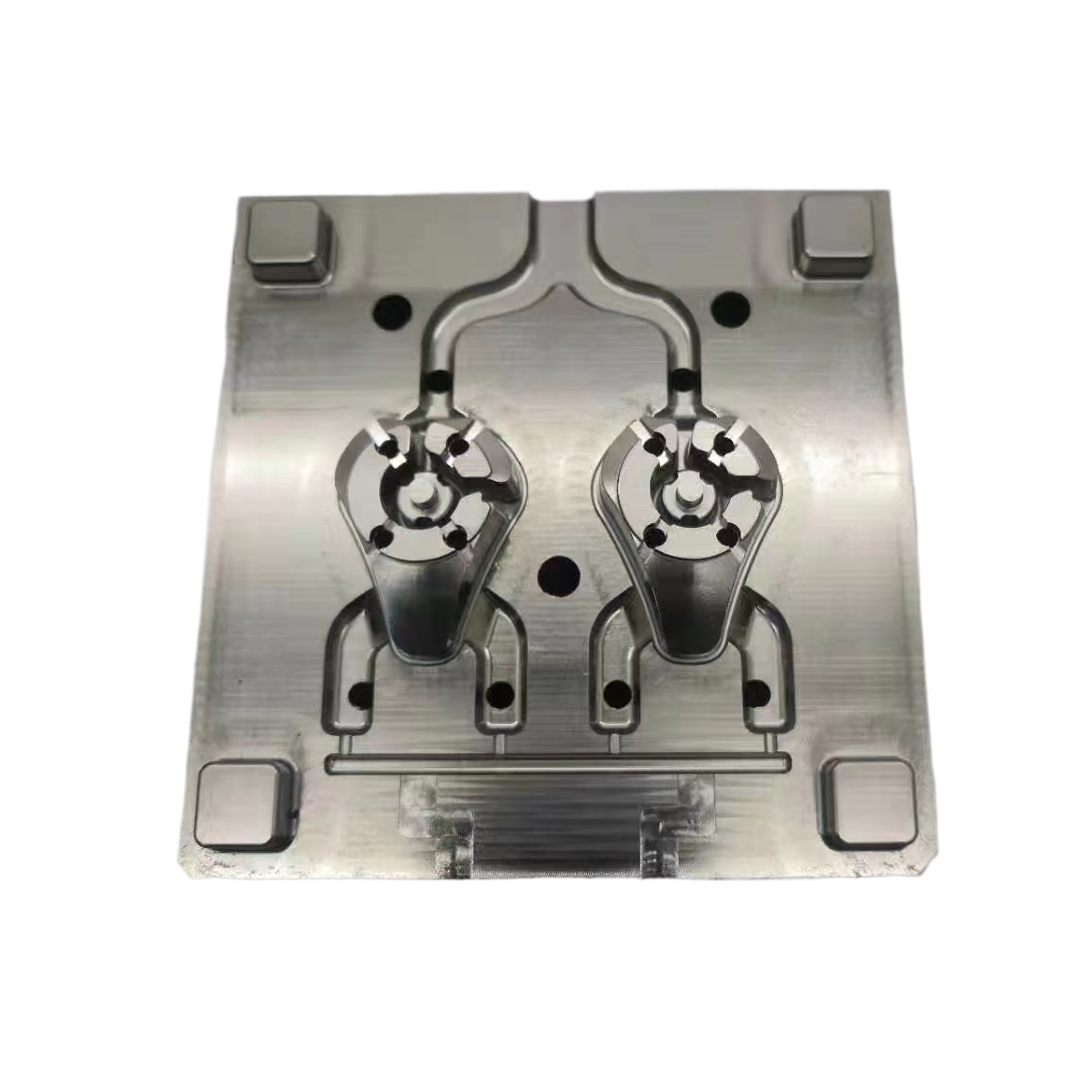

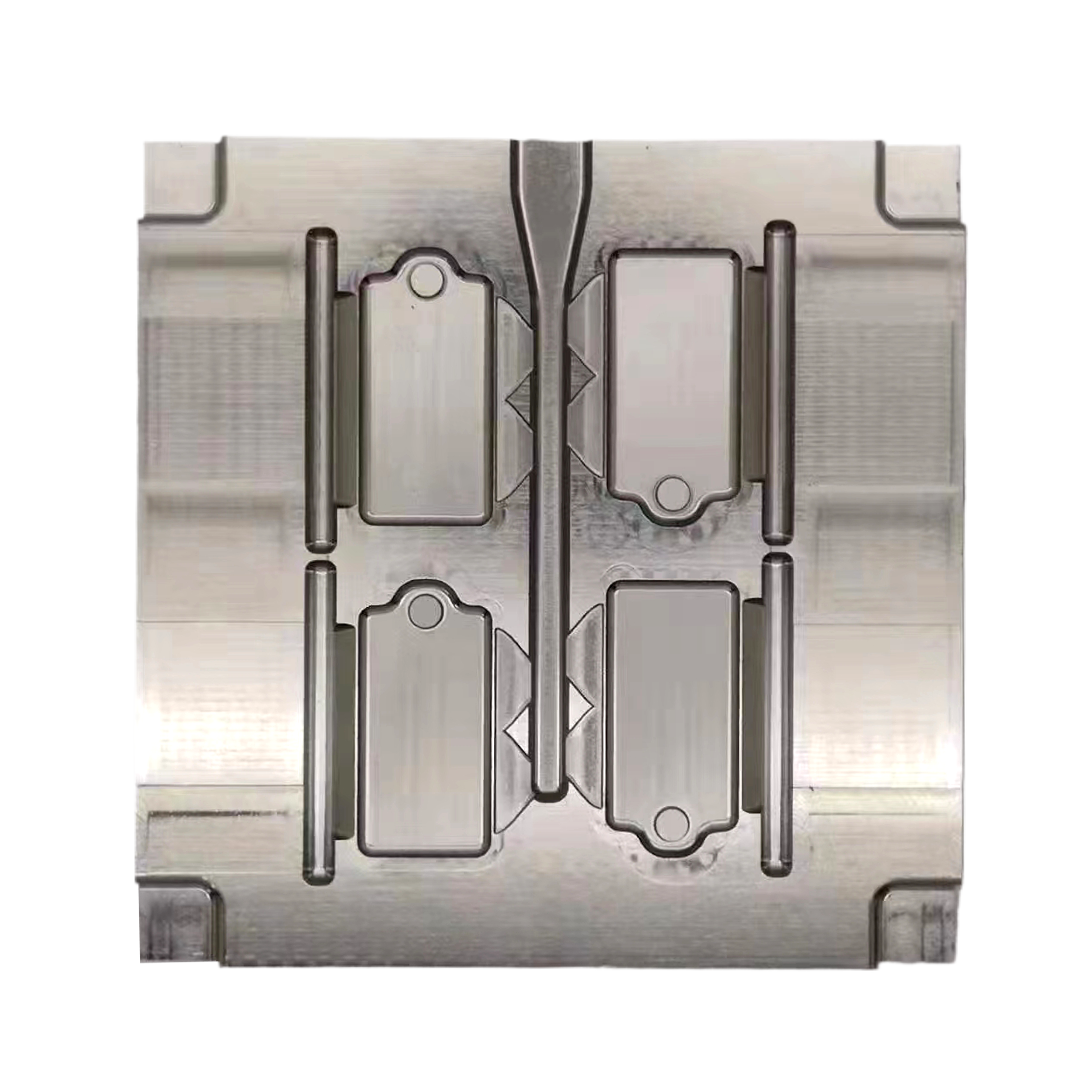

Molds

-

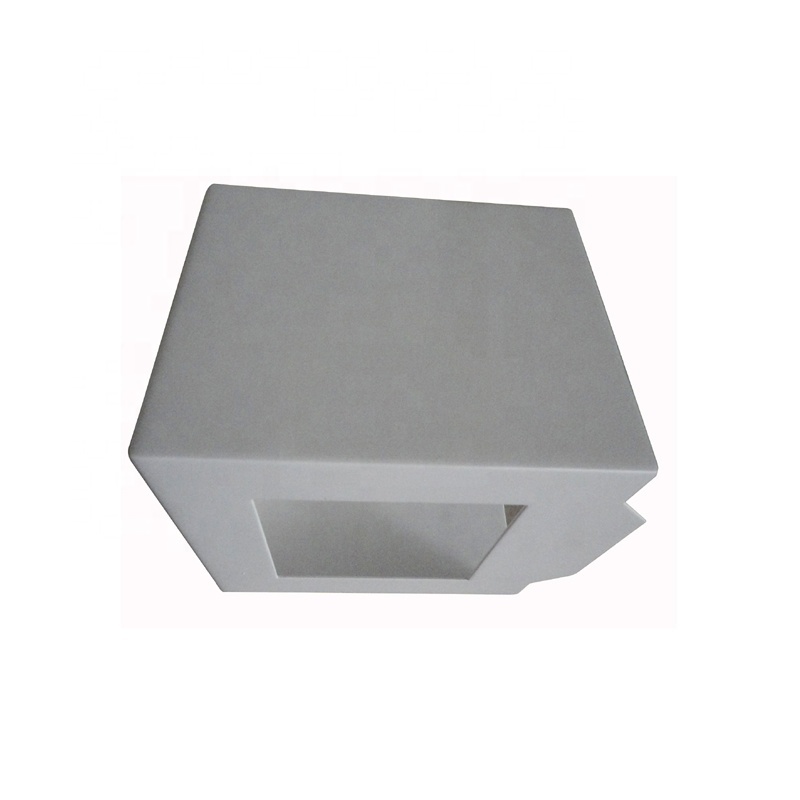

Mold

1. Material: SD/LKM Standard/HASCO Standard Self-made 2. Price: Factory Price 3. Manufacturing Service: OEM or ODM is available. 4. Tolerance: down to +/-0.01mm, high accuracy 5. Specification: Products can be produced as per client’s drawings. 6. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 7. Manufacturing Processes and Procedures: cnc machining

-

High precision set

1. Material: SD/LKM Standard/HASCO Standard Self-made 2. Price: Factory Price 3. Manufacturing Service: OEM or ODM is available. 4. Tolerance: down to +/-0.01mm, high accuracy 5. Specification: Products can be produced as per client’s drawings. 6. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 7. Manufacturing Processes and Procedures: cnc machining

-

Mold

1. Material: SD/LKM Standard/HASCO Standard Self-made 2. Price: Factory Price 3. Manufacturing Service: OEM or ODM is available. 4. Tolerance: down to +/-0.01mm, high accuracy 5. Specification: Products can be produced as per client’s drawings. 6. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 7. Manufacturing Processes and Procedures: cnc machining

-

Mold

1. Material: SD/LKM Standard/HASCO Standard Self-made 2. Price: Factory Price 3. Manufacturing Service: OEM or ODM is available. 4. Tolerance: down to +/-0.01mm, high accuracy 5. Specification: Products can be produced as per client’s drawings. 6. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 7. Manufacturing Processes and Procedures: cnc machining

-

Mold

1. Material: SD/LKM Standard/HASCO Standard Self-made 2. Price: Factory Price 3. Manufacturing Service: OEM or ODM is available. 4. Tolerance: down to +/-0.01mm, high accuracy 5. Specification: Products can be produced as per client’s drawings. 6. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 7. Manufacturing Processes and Procedures: cnc machining

-

Mold

1. Material: SD/LKM Standard/HASCO Standard Self-made 2. Price: Factory Price 3. Manufacturing Service: OEM or ODM is available. 4. Tolerance: down to +/-0.01mm, high accuracy 5. Specification: Products can be produced as per client’s drawings. 6. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 7. Manufacturing Processes and Procedures: cnc machining

-

Mold

1. Material: SD/LKM Standard/HASCO Standard Self-made 2. Price: Factory Price 3. Manufacturing Service: OEM or ODM is available. 4. Tolerance: down to +/-0.01mm, high accuracy 5. Specification: Products can be produced as per client’s drawings. 6. Drawing Software: CAD/Solidworks/CAXA/UGNX.10 7. Manufacturing Processes and Procedures: cnc machining

Inquiry Consulting

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.