CAPABILITY

CAPABILITY

Quality Management

Zhenxin utilises rigorous processes to ensure the highest manufacturing standards for your custom parts, inspecting dimensions and visual aspects both during and after production to deliver on-time and precisely tailored components.

- Our quality management processes are ISO 9001 certified

- We ensure that we meet all of our customers' QA requirements, from initial sampling to monitoring and documentation of series production.

- Our in-house labs and external labs can provide quality inspection reports (Standard, FAIR, CMM)

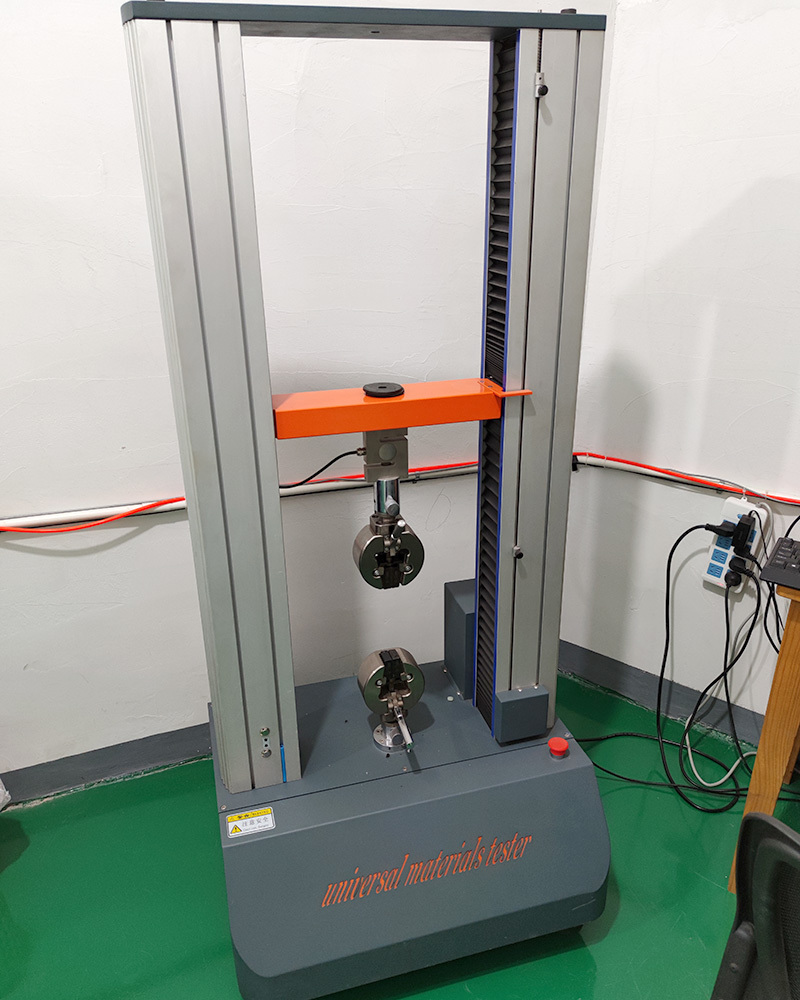

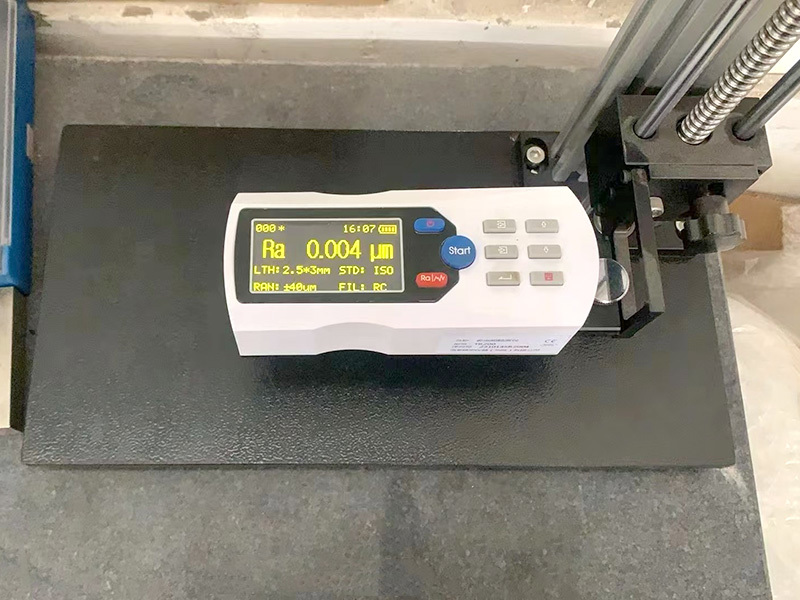

Equipment Used for Quality Control

We have the latest equipment to perform inspections your way:

- In-line CAD stations for our technicians

- Part drawing creation to your datum schemes

- Measuring equipment certification programs

- Coordinate measurement machine (CMM) from Mitutoyo

- Shadowgraph devices

- Mass spectrometer (XRF) to validate material compositions

- Ring and thread gauges

- Gage blocks and gage pins

- Assortment of micrometres and callipers

Inspection Services Offered by Zhenxin

Inspection services play a vital role in ensuring quality control and compliance with standards in various industries. If required, Zhenxin can provide customers with the following quality control certifications:

- Standard Measurement Protocol: This protocol ensures consistency and accuracy in measurements, reducing errors and variations. It involves using calibrated measurement tools and following specific guidelines to verify dimensional accuracy, tolerances, and other relevant specifications.

- First Article Inspection Report (FAIR): It is typically required for the initial production run of a new product or component. It involves a comprehensive examination and measurement of a representative sample from the first production batch. The FAIR verifies that the product meets all specified requirements, including design specifications, engineering drawings, and contractual obligations.

- CMM Report: CMM stands for Coordinate Measuring Machine, which is a highly precise measurement system used to inspect the geometric characteristics of objects. A CMM Report provides detailed information on the measurements obtained using this machine, such as data on dimensional accuracy, form, orientation, and position of features.

Quality Documentation We Can Provide

To ensure that our orders meet our clients’ standards, we control the quality strictly and can furnish certifications and reports as needed. The following quality documents are available for all our manufacturing technologies (CNC machining, sheet metal fabrication, 3D printing and injection moulding).

- CMM Inspection Report

- Material Certificate (for metals only)

- Standard Measurement Protocol

- First Article Inspection Report (FAIR)

- RoHS (Restriction of Hasardous Substances Directive)

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals)

- Certificate of Conformance

Our professionally-trained quality engineering team continuously improves the quality control process to bring you part quality peace of mind on every single order.

Previous:

Next:

Social Media

Contact Information

Xiamen Zhenxin Hardware Products Factory

Add:No.61, North Tongsheng Road, Xiamen City, Fujian Province, China 361100

Tel: 86-592-5510647

Mobile: 86-13799290621

E-mail: zhenxin@zxindustry.com

All Rights Reserved © 2024 Xiamen Zhenxin Hardware Products Factory

Cookie

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

Cookie

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.