Die Casting Parts: The Backbone of Reliable Hardware Solutions

Release time:

Dec 10,2025

Description: Die Casting Parts: The Backbone of Reliable Hardware Solutions

Table of Contents

Introduction to Die Casting Parts

What is Die Casting?

Advantages of Die Casting in Hardware Solutions

Applications of Die Casting Parts

The Die Casting Process Explained

Types of Die Casting Techniques

Material Selection for Die Casting Parts

Quality Control in Die Casting Manufacturi

Die Casting Parts: The Backbone of Reliable Hardware Solutions

Table of Contents

- Introduction to Die Casting Parts

- What is Die Casting?

- Advantages of Die Casting in Hardware Solutions

- Applications of Die Casting Parts

- The Die Casting Process Explained

- Types of Die Casting Techniques

- Material Selection for Die Casting Parts

- Quality Control in Die Casting Manufacturing

- The Future of Die Casting in Manufacturing

- Frequently Asked Questions

- Conclusion

Introduction to Die Casting Parts

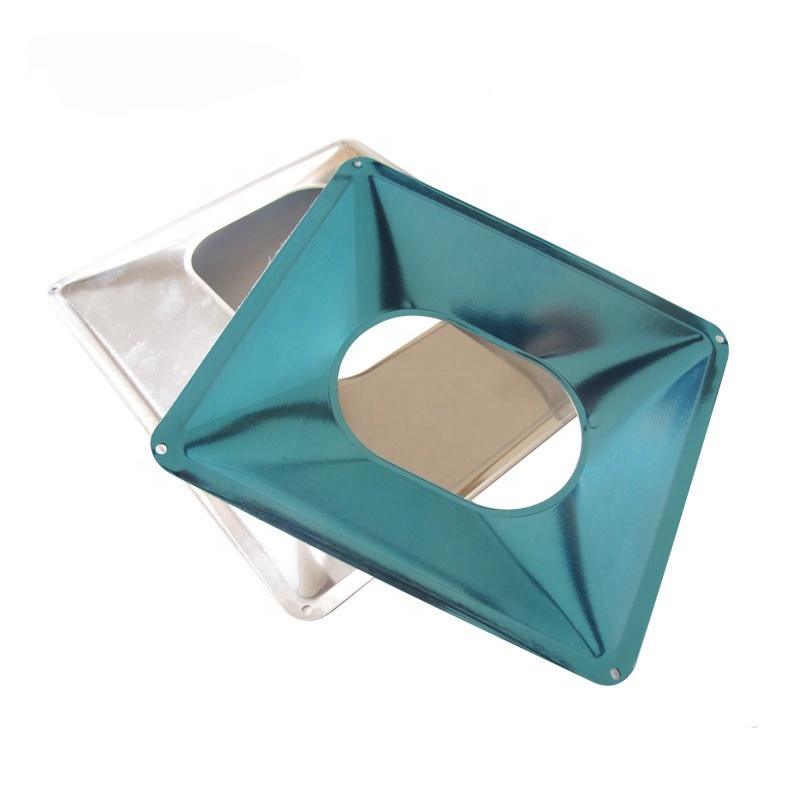

Die casting parts play a pivotal role in the hardware industry, providing manufacturers with a reliable solution for various applications. The die casting process allows for the creation of complex shapes with high precision and repeatability. As industries evolve, the demand for strong, lightweight, and cost-effective components continues to rise, making die casting an indispensable method in the production of hardware solutions.

What is Die Casting?

Die casting is a manufacturing process that involves forcing molten metal into a mold cavity under high pressure. The molds, or dies, are typically made from steel and are designed to withstand the high temperatures and pressures involved in the casting process. This method is particularly favored for its ability to produce parts with intricate geometries and superior surface finishes, making it ideal for various hardware applications.

Advantages of Die Casting in Hardware Solutions

Die casting offers numerous advantages over other manufacturing processes. These include:

1. High Precision and Consistency

The high-pressure injection of molten metal into molds ensures that even the most complex shapes can be reproduced with consistent accuracy. This level of precision is critical in applications where tolerances are tight, such as in automotive and aerospace industries.

2. Enhanced Durability

Die cast parts are known for their strength and durability. The process creates a dense and solid structure, making these components ideal for heavy-duty applications where reliability is paramount.

3. Cost-Effectiveness

While the initial setup for die casting can be higher than other methods, the long-term savings realized from reduced scrap rates and lower labor costs make it a cost-effective solution for mass production.

4. Versatility in Material Use

Die casting works with a variety of metals, including aluminum, zinc, and magnesium, allowing manufacturers to choose the best material for their specific needs.

Applications of Die Casting Parts

Die casting parts are utilized across a wide range of industries due to their unique characteristics. Here are some prominent applications:

1. Automotive Industry

In the automotive sector, die cast components are used for engine blocks, transmission cases, and various other parts. The lightweight nature of materials like aluminum improves fuel efficiency and performance.

2. Aerospace

The aerospace industry demands components that can withstand extreme conditions. Die casting parts provide the necessary strength-to-weight ratio, making them ideal for aircraft components.

3. Electronics

Die casting is used in the manufacturing of housings and structural components for electronic devices. The precision achieved ensures the proper fit and function of various electronic parts.

4. Medical Devices

In medical applications, die casting parts are used where sterility and reliability are critical. Components for medical instruments and devices benefit from the durability and precision of die casting.

5. Home Appliances

Many household appliances utilize die cast parts for their robustness and aesthetic appeal. From kitchen devices to power tools, the durability of these components enhances product longevity.

The Die Casting Process Explained

The die casting process encompasses several critical steps:

1. Preparation

The process begins with preparing the die. This involves cleaning and applying a release agent to ensure that the finished part can be easily removed from the mold.

2. Melting the Metal

The selected metal is heated in a furnace until it reaches a molten state. This step requires careful temperature control to ensure optimal fluidity during injection.

3. Injection

Once the metal is molten, it is injected into the die under high pressure. This rapid injection fills the mold quickly, minimizing the chance of defects.

4. Cooling

After injection, the molten metal cools and solidifies within the mold. Effective cooling is essential for achieving the desired mechanical properties.

5. Ejection

Once the part is solidified, it is ejected from the mold. Any necessary finishing processes, such as trimming or machining, are performed at this stage.

Types of Die Casting Techniques

Die casting can be categorized into several techniques, each offering unique benefits. The two primary types are:

1. Hot Chamber Die Casting

This technique is suitable for metals with low melting points, such as zinc. The molten metal is kept in a chamber that is heated, allowing for rapid production rates.

2. Cold Chamber Die Casting

Cold chamber die casting is used for metals with higher melting points, like aluminum. The molten metal is poured into the chamber, making it more versatile but generally slower than hot chamber casting.

Material Selection for Die Casting Parts

Choosing the right material is crucial for the performance of die cast parts. Factors to consider include:

1. Strength Requirements

Different applications require varying levels of strength. Aluminum is often chosen for its lightweight properties, while zinc offers excellent corrosion resistance.

2. Thermal Conductivity

For electronic applications, materials with high thermal conductivity are essential to dissipate heat effectively.

3. Finish and Aesthetics

Some applications may require specific surface finishes to enhance appearance or functionality. The material selected should accommodate additional finishing processes if needed.

Quality Control in Die Casting Manufacturing

Ensuring the quality of die cast parts is essential for maintaining reliability and performance. Effective quality control measures include:

1. Inspection During Production

Regular inspections during the production process help identify defects early. This proactive approach minimizes waste and ensures high standards are met.

2. Testing for Mechanical Properties

Testing parts for tensile strength, hardness, and fatigue resistance ensures they meet industry standards and application requirements.

3. Final Product Testing

Before parts are shipped, final inspections verify that they meet specifications regarding dimensions, surface finish, and overall quality.

The Future of Die Casting in Manufacturing

The future of die casting looks promising, driven by advancements in technology and material science. Innovations such as 3D printing combined with die casting techniques are emerging. These developments can lead to more efficient designs and reduce production costs.

In addition, the focus on sustainability is influencing the die casting industry. Manufacturers are exploring eco-friendly materials and processes to minimize their environmental impact. This shift will likely reshape how die cast parts are produced and utilized across various industries.

Frequently Asked Questions

1. What metals are commonly used in die casting?

Aluminum, zinc, and magnesium are the most commonly used metals due to their favorable properties.

2. Is die casting suitable for small production runs?

Die casting is generally more cost-effective for large production runs, but it can be adapted for smaller batches depending on project requirements.

3. What are the typical lead times for die casting parts?

Lead times can vary based on complexity and order size but generally range from several weeks to a few months.

4. Can die cast parts be recycled?

Yes, many die cast metals, especially aluminum and zinc, are highly recyclable, making them an environmentally friendly option.

5. How does die casting compare to other manufacturing processes?

Die casting offers superior precision, strength, and surface finish compared to methods like sand casting and machining, especially for high-volume production.

Conclusion

Die casting parts represent a foundational element in the hardware industry, providing essential solutions that blend strength, precision, and cost-effectiveness. The advantages of die casting, combined with its diverse applications, position it as a key player in modern manufacturing. As technology evolves and new materials are developed, die casting is set to remain at the forefront of hardware solutions, continuing to meet the demands of various industries for years to come.