The Comprehensive Guide to Powder Coating Steel Springs: Enhancing Durability and Functionality

Release time:

Dec 09,2025

First and foremost, powder coating provides superior corrosion resistance. Steel is susceptible to rust and degradation when exposed to moisture and environmental elements. By applying a powder coat, the springs are shielded from oxidation, which can significantly extend their lifespan. This is particularly beneficial for springs used in outdoor applications or in environments with fluctuating temperatures and humidity levels.

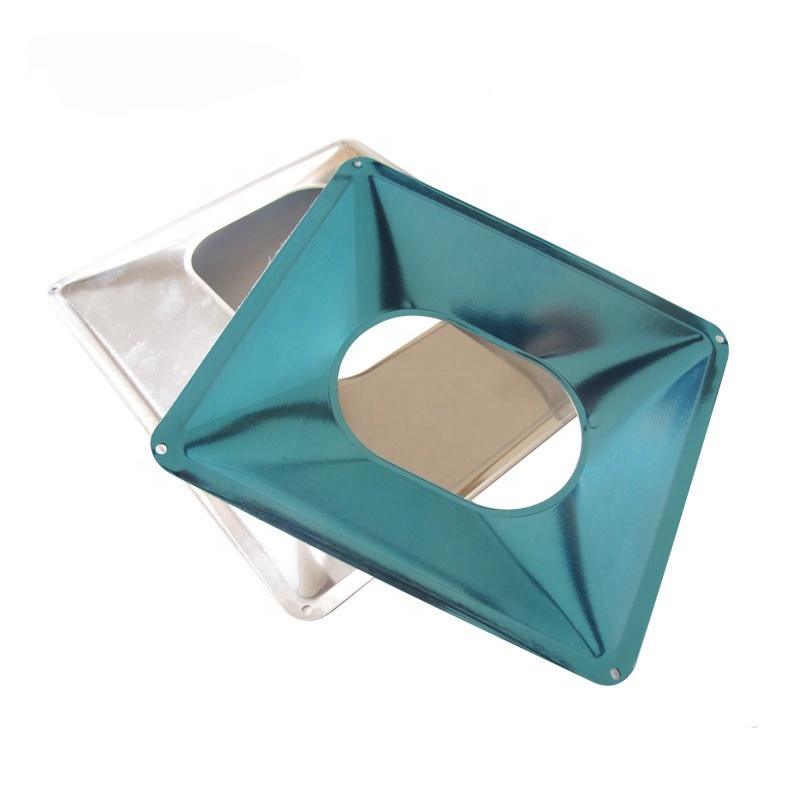

Furthermore, powder coating enhances the aesthetic appeal of steel springs. Available in a diverse range of colors and finishes, powder coating allows manufacturers to create visually appealing components that can complement the overall design of machinery or equipment. This is particularly important in consumer-facing products where appearance can influence buyer perception.

Another key benefit of powder coating steel springs is its durability. The cured finish provides a hard, resilient surface that is highly resistant to impacts, scratches, and other forms of mechanical wear. This durability translates to lower maintenance costs and reduced frequency of replacements, which can significantly benefit manufacturers aiming to improve efficiency and reduce operational downtime.

In addition to these advantages, the powder coating process is environmentally friendly. Unlike traditional liquid coatings, powder coatings emit little to no volatile organic compounds (VOCs) during application. This makes powder coating a more sustainable option for manufacturers looking to minimize their environmental impact while still achieving high-quality finishes.

Moreover, the application process itself is highly efficient. Powder can be easily applied through electrostatic spraying, ensuring even coverage and reducing material waste. Once cured, the coating adheres firmly to the steel, resulting in a consistent, uniform finish that enhances the overall performance of the springs.

In conclusion, powder coating steel springs is an advantageous process that provides significant benefits in terms of durability, resistance to environmental factors, and aesthetic appeal. By investing in this finishing technique, manufacturers can ensure that their springs meet the rigorous demands of various applications, thereby enhancing their overall performance and longevity in the market. Properly coated steel springs can contribute to the reliability and efficiency of machinery, making them a valuable component in any manufacturing setup. Embracing powder coating as a standard practice can lead to enhanced product offerings and increased customer satisfaction in the competitive spring manufacturing industry.

Social Media

Contact Information

Xiamen Zhenxin Hardware Products Factory

Add:No.61, North Tongsheng Road, Xiamen City, Fujian Province, China 361100

Tel: 86-592-5510647

Mobile: 86-13799290621

E-mail: zhenxin@zxindustry.com

All Rights Reserved © 2024 Xiamen Zhenxin Hardware Products Factory

Cookie

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

Cookie

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.