Specialty

Specialized with Rich experience in metal fabrication and plastic injection molding manufacture in China. (More than 20 years). We provide OEM/ODM services for different countries.PRODUCTS

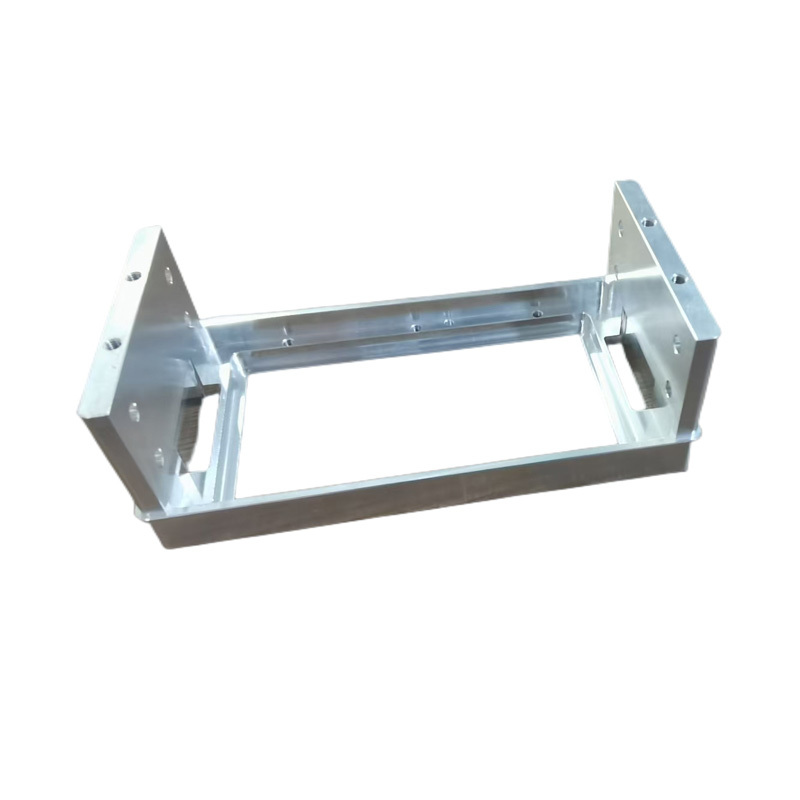

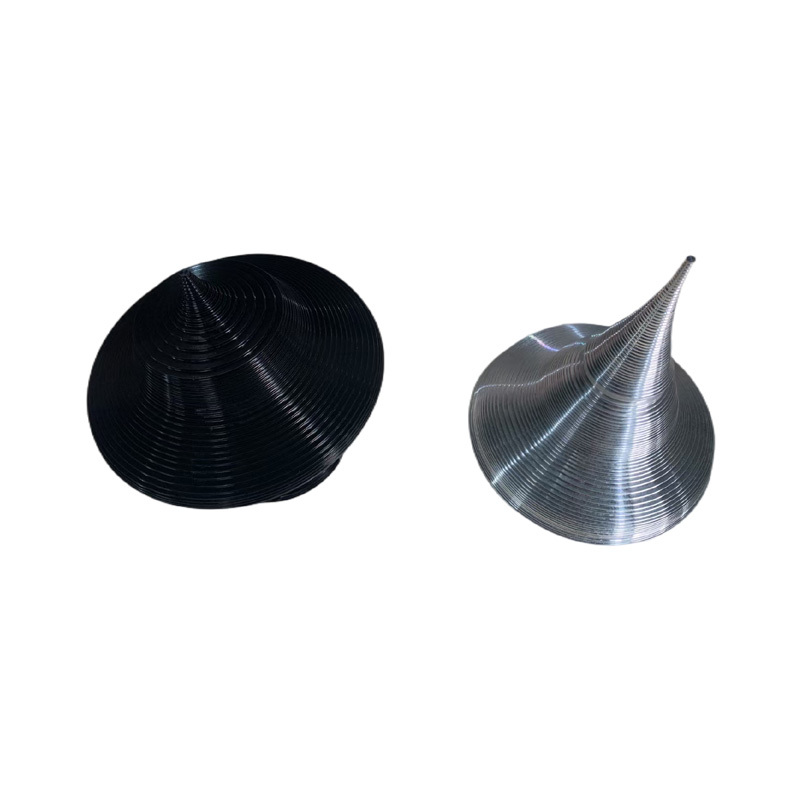

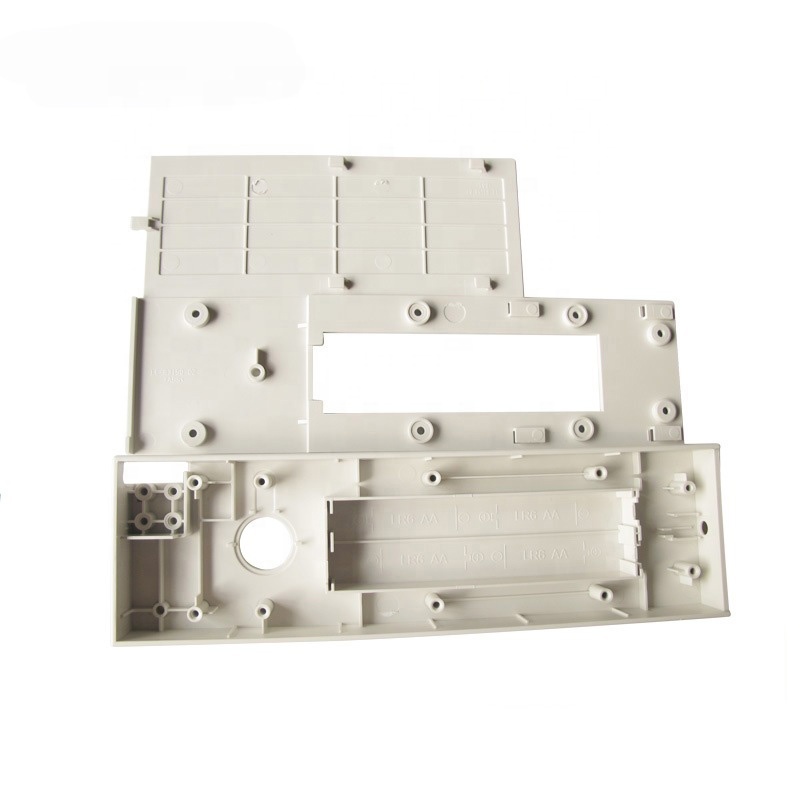

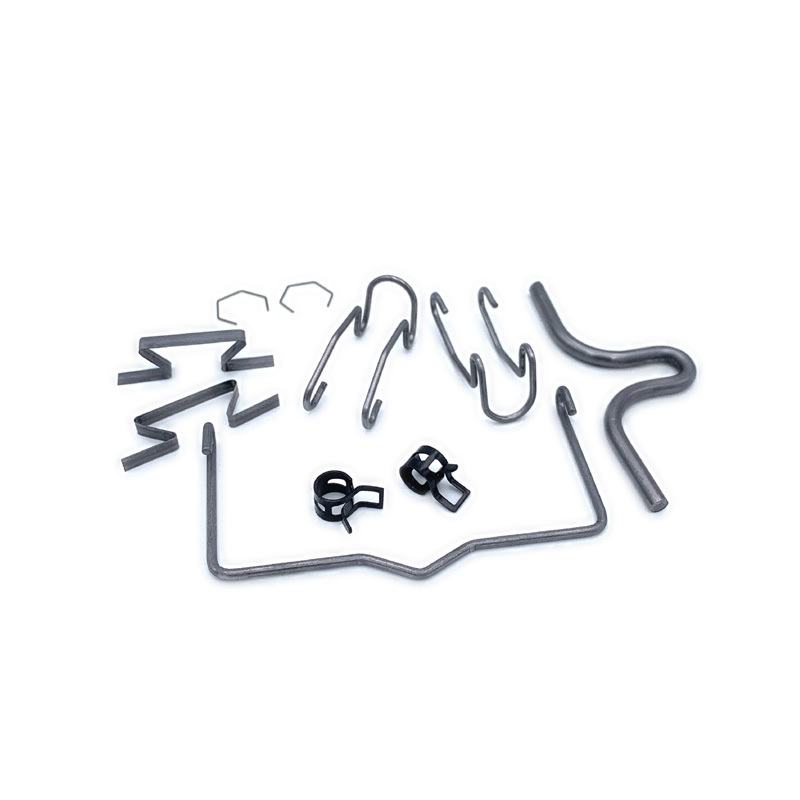

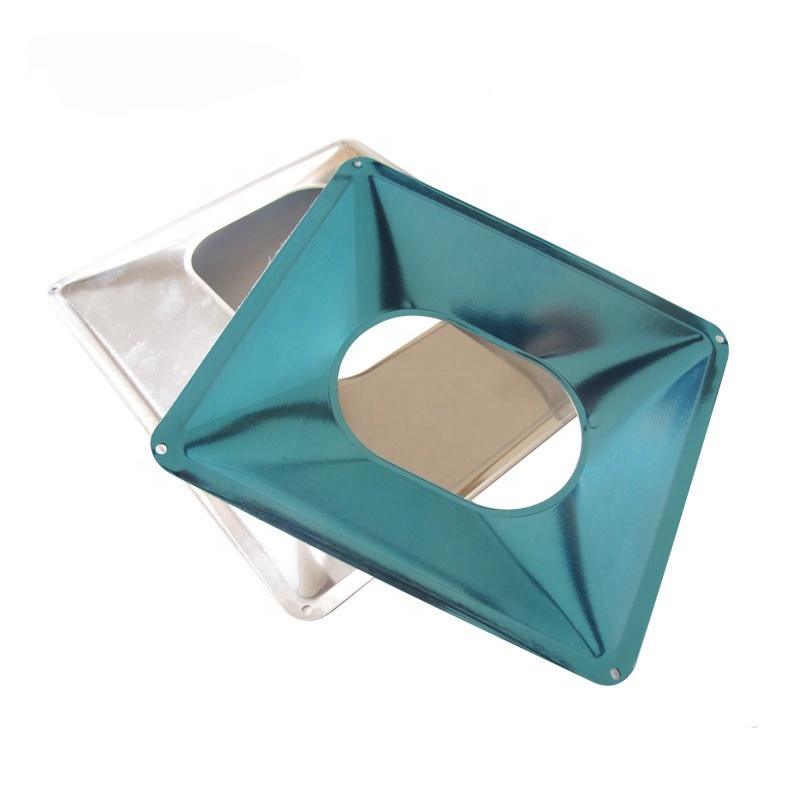

Provides High-Quality Manufacturing Solutions For Producing Metal & Plastic Parts

ABOUT US

Established in 2005

Zhenxin Hardware Products

Xiamen Zhenxin Hardware Products Factory was founded in 2005 at Xiamen China (mainland), and has grown to become the preferred supplier of custom parts for businesses, engineers and inventors around the world. Our factories cover an area of 10000 square meters and have more than 150 employees. With more than 20 years' experience in the industry and an experienced engineering team with ISO 9001: 2015 quality system, we are able to provide one-stop solution from design, prototypes, mold to mass production in volume.

We have over 20 years of production experience

Covering an area of 10,000㎡

Have more than 150 skilled workers

We have 30 professional engineers

OUR ADVANTAGES

We Create A Win/Win Experience For All Involved

ONE-STOP SOLUTION

Provide services from design, mold, machining, surface treatment, printing, assembly, packing to shipping.

LOW MOQ

Easily customized your parts with just 1pcs.

FREE DESIGN

Create fully customized parts with your sample or idea.

FREE SAMPLE

Provide free sample before mass production

PRODUCTION PROCESS

We make every effort to optimize the production process to meet your needs

ZHENXIN

WHY CHOOSE US

-

-

Production

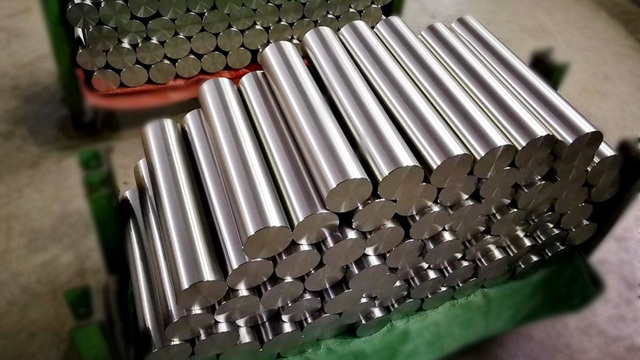

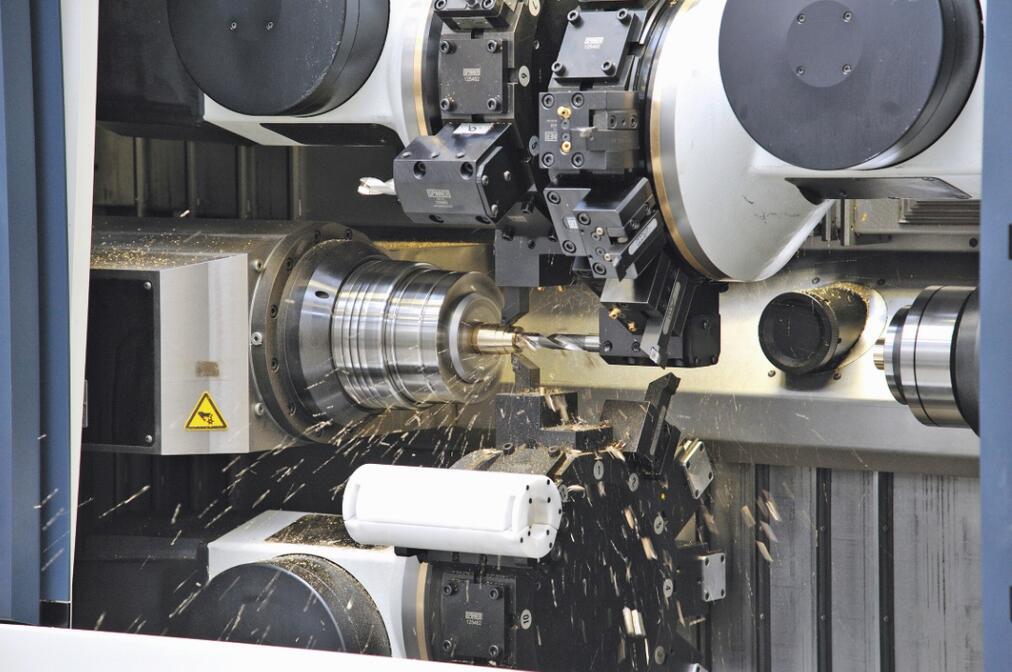

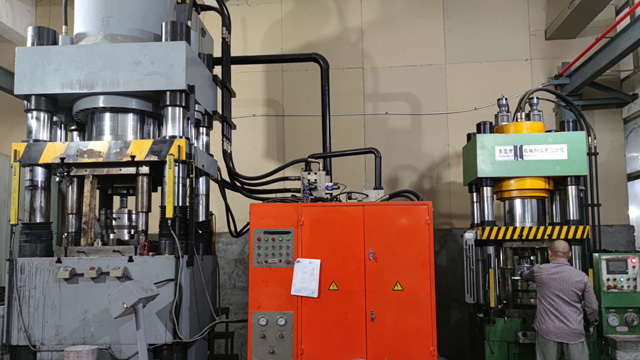

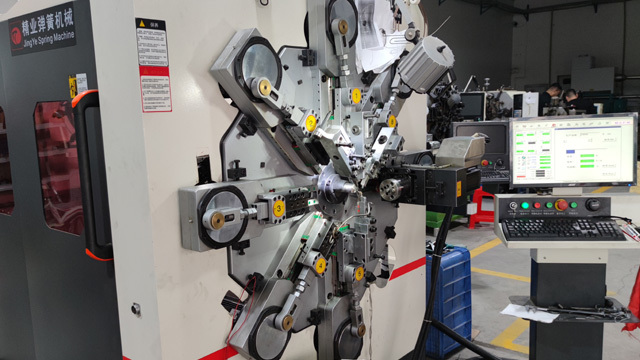

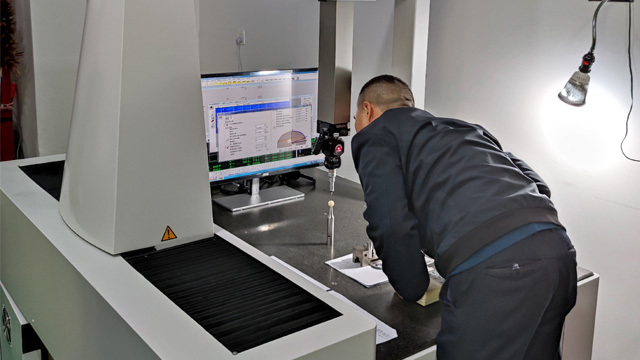

We keep adopting advanced production facilities to improve efficiency and ensure high and stable quality, and further reduce the production cost. -

Technical team

We profit of 15% to 20% per year on research and development work, more than 12 engineers of the technical team for product research and development work, and are able to create products to meet the specific needs of our customers for OEM base. -

Quality

We got the ISO9001 management system certification, establish and improve the quality management system, Establishing and perfecting the enterprise self-control, social supervision, government supervision, user evaluation "project quality management mechanisms. -

One-stop Solution

We have our own technology team, cnc machining workshop, stamping workshop, plastic injection workshop, mold workshop, printing workshop and QC team, are able to provide one stop solution for custom metal or plastic parts you need from design, prototype, mold development, production , logo printing, surface treatment to shipment, so that make your design become a reality and save your cost and energy. -

Service

We are not only a high-performance and experienced developer and supplier, but also see ourselves as a competent and flexible service provider. Beyond pure manufacturer activity, we are also committed to integrating high-quality supply chain resources to provide our partners with a variety of processing technologies.

ENVIRONMENTAL EQUIPMENT

We Offer A Wide Range Of Technologies And The Associated Processing Options.

NEWS INFORMATION

We support free sample design, 24-hours sale service and technology service

SEND YOUR INQUIRY

We will contact you within 1 working day, please pay attention tothe email with the suffix "@zxindustry.com"

Ask Product Manual NowWould you like to know more about our products?please fill inthe form on the left. in addition, you can send us a detailedlist of your requirements.

The information we can provide:

√ we are able to provide one-stop solution from design, prototypes, mold to mass production in volume.